Our Self-propelled harvester celebrates it debut at Agritechnica in Hannover !

At this year’s Agritechnica, Schmiede.one, the innovation laboratory of the Grimme Group, presents a compact self-propelled harvesting machine, which can optionally be extended to an autonomous robot.

Harvey.one is our first step towards autonomous robotics and can be used as a multifunctional equipment carrier. Our first application for Harvey.one was the root crop harvest, especially the sweet potato.

The idea was born when we were dealing a lot with sweet potatoes as cultivated vegetables in the German market and exchanged ideas with farmers from our region. Due to the complex and manual harvesting process, we have been working on our machine since the beginning of the year. For the purpose of targeted communication with our users, the farmlab.one website was set up, with which we constantly report on the progress of the project.

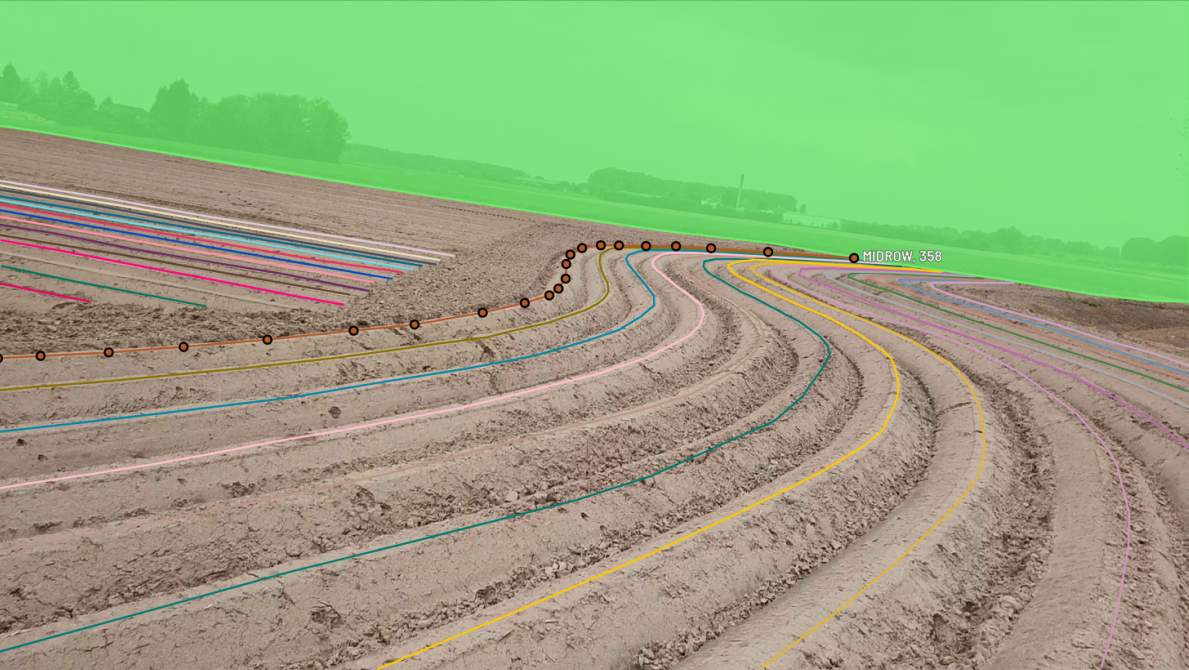

During the development of the machine we received support from the Grimme Group to combine proven technology with innovative software solutions. In the software area we use sensors for device location (GPS/RTK), field navigation (IMA/Xaver) and object recognition (3D camera technology) and thus take the first steps towards an autonomous navigating machine. At Harvey.one we rely on a tried and tested Grimme camera with gentle, rubberized sieve belts and hydraulic drive to guarantee gentle product handling.

It is our aim to offer a solution for smaller, agricultural enterprises with our product, which are not sufficiently served with currently available technology. Variety and smaller parcels resulted in a low degree of mechanization and a high degree of manual work.

Sweet potatoes represent an exotic vegetable that is new to German cultivation and is often grown on small areas. Accordingly, there is currently no suitable technology on the market that would allow mechanisation here as well. We want to offer our technology not only for direct sale, but also as a service for the farmer. The aim is to make it easier for farmers to enter new vegetable varieties through low investment costs.

At Agritechnica we look forward to meeting farmers and receiving feedback from visitors. In addition to machine presentations, we will also be happy to exchange general information about sweet potatoes and give tips on cultivation and marketing.

You will find us in hall 25 at stand G06 (Grimme Group).